1911 Feeding (Ep.1) | Extractor Clocking | 1911 Tech

0%

This video will be the first installment of our 1911 Feeding Series where we will address common feeding issues in 1911 pistols and how to fix them. This video will cover Extractor Clocking and how to fix it. As always if you have any questions leave them down in the comments and have a great day from the Fusion Firearms Family!!!

Video Transcript

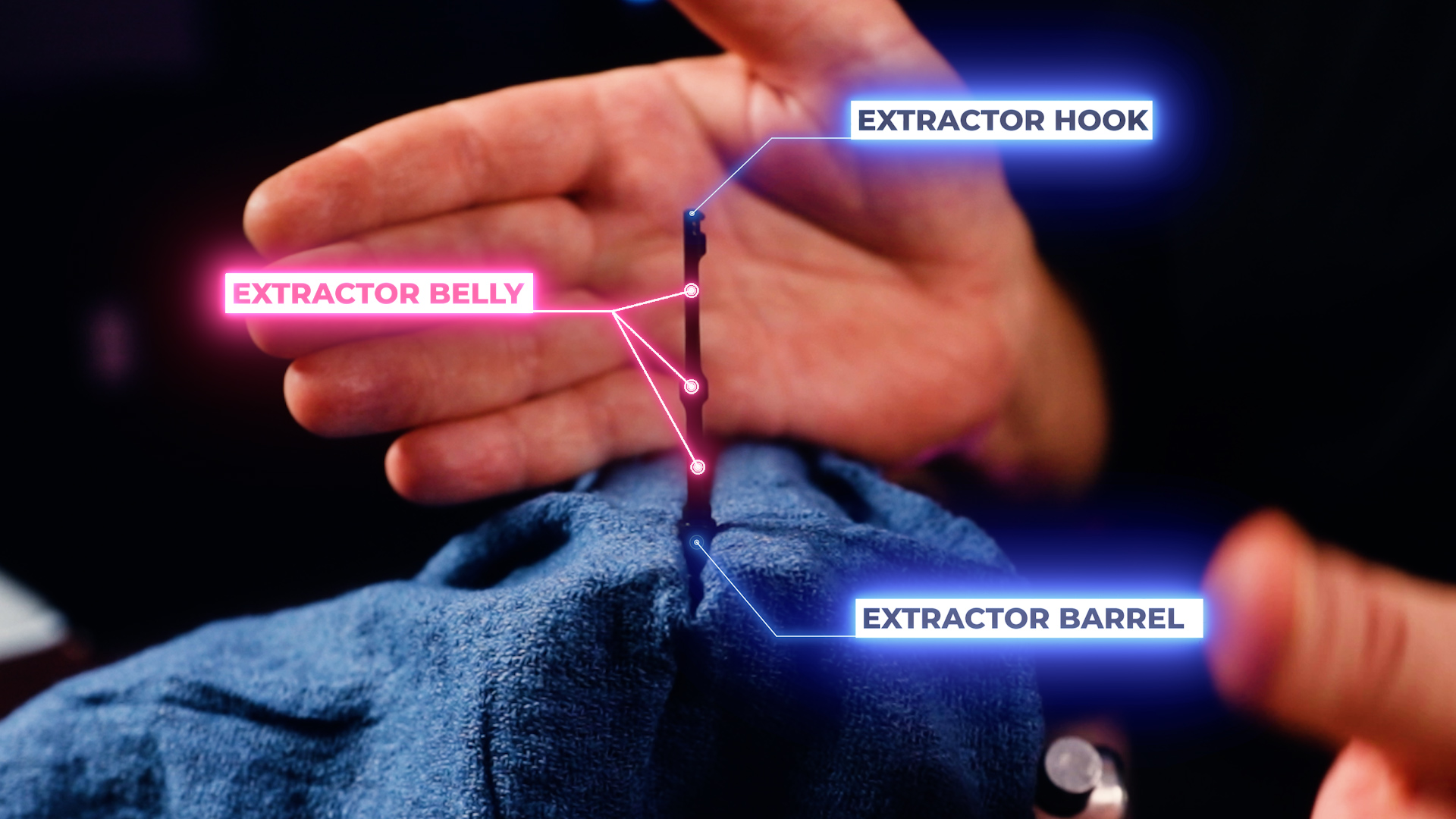

hi folks we're starting our feeding in the 1911 topics uh today we're going to go over extractor clocking what does that mean to you how can you recognize if your extractor is clocking and how do you remedy that that's nick hi folks bob from fusion firearms again uh today we're going to get into as I promised uh feeding extraction ejection issues we're going to start working on that with the 1911. what do certain things attribute to and how do you fix those today what we're going to do we'll start with extractor clocking a lot of people don't understand what the extractor clocking is and what it basically is uh when your extractor while you're firing is moving because the stop plate is fitted quite sloppily in the in the actual pistol itself and the slide so how do you what do you want to what are one of the uh causes uh when you're shooting uh of extractor clocking well one is generally uh you'll see and again this this is not always the norm okay but it is it is uh kind of consistent with the issue um generally you'll see erratic uh ejection of your cartridges meaning you know one time it's going here one time it's going here one time it's going forward one time it's going over your head now there are other things that can lead to that happening okay but uh extractor clocking is a big issue with that so how do you know if you have extractor clocking and again so many factory guns that we work on here the extractors are sloppy to begin with and a lot of times for the amount of shooting people are doing they don't really notice they don't care you know it's still working for them so it doesn't really bother so again is that an issue for you or not maybe it is maybe it isn't okay it really again depends on the function of the gun and if the gun's functioning fine you're happy with it leave it the way it is um if you do have issues with the ejection you're not happy with it then again this is something to investigate is extractor clocking now again what is the extractor well the extractor's right here and show you some detailed pictures of it in the back of the slide again these slides are pretty much gutted we took the barrel out and everything just to kind of show you and focus on this point right now so how do I usually simply uh check extractor clocking well I usually use a screwdriver okay or I use my favorite scribe here which I use for almost everything and what it’ll do here is basically I’m just going to take the slide I’m going to hold it and I’m going to take it and I’m going to rub with the stop plate and firing pin in I’m just going to rub this back and forth on the back flat of the extractor and when I do that in this gun ah I can see it's clocking a little bit not much but it is clocking okay and what that means is as I move pressure up and down on that flat from the bottom to the top I can watch this extractor doing this in the gun okay I’m exaggerating with my hand of course but that's what I’m saying it can actually clock that's what people mean by clocking extractor so again as you're firing an extractor is moving around of course it's putting different tension on the casings feeding up onto the breech face so again you're going to get all types of weird ejection at times and that can be a an issue uh with the clocking here's another example of the slide and again I’ll take my lucky scribe here and I’m going to rub on the back and no that doesn't move at all and we'll show you some close-ups of this also and you can see as I’m pushing on it on the top and the bottom that extractor is dead solid and they're not moving okay so what can attribute to clocking all right well a couple of things one is extractor tension itself that that can be part of it and we'll show you a few ways to fix clocking that way and generally what you'll end up doing if you want to fix your extractor clocking it's going to be a combination of the extractor barrel itself which is the back barrel on here and the actual uh slide stop itself okay the slide stop and again on most mil-spec guns um you're going to find that the firing pin stop is a drop-in and that's made that way for a reason so you can fix it in the field but generally when you when you have a drop in firing pin stop you are going to end up with a little bit of clocking on the on the extractor because it's not fit real tight to the firing pin stop or excuse me not to slide stuff the firing pin stopped so I kind of screwed that up so if I said slide stop I meant firing pit stop and we just did a slide stop video so I’m on that right now so anyway see when you go here if the if the slide stop is not fit tight um you will get clocking slide stop I just said slice off again okay [ __ ] okay folks I’m back hopefully I got the firing pin stop out of my brain and we're on the firing pin stop okay so you guys remind me okay remind me if I say it again wrong put it in the comments again you know any way you can help me uh clarify what I’m trying to say here anyway it's a slide stop or the firing pit stop not the slide stop too many videos today all right so the firing pin stop all right so if that's not tight again it'll you'll end up clocking on your extractor um and that that'll be one of the causes so again how do we how do we correct that all right so we'll take the we'll take let's see here this pistol or slide here and what I’m going to do here is I’m going to take this is the one that was clocking slightly and again we'll show you some close-ups of this and again it's just pressure on the top pressure on the bottom so I’m going to take the firing pin stop out got it right give me a gold star so how do I take the firing pin stop out so generally I have a punch like this again it's one of my favorite punches and you know it's uh it's basically an eighth inch punch and I grind a little radius on the end and what I usually do is I’ll put some on a bench block put some pressure on the top of the slide you'll see how I’m positioning my fingers we'll get a couple of close-ups of this also and I’ll push in on the firing pin and just tap slightly on the slide stop bringing it see how it dropped right out and then relax the firing pin spring and that'll come right out okay so there you have your spring your firing pin your slide stop now we're going to take the extractor out usually on the extractor I have actually knew a new screwdriver this one's a little big usually the small gray screwdrivers I use um but I’ve broken them all this week a little too heavy on the work but you'll see how this extractor really is kind of loose in this slide and I can pretty much almost drop it right out so when I look at the extractor you know you have basically uh in the front you have your extractor hook you'll have the belly here of the extractor and you'll have the barrel which I call this the barrel of the extractor where you have the groove cut into it for your firing pin stop so again now what way do we normally fix this most guys will there's a couple ways of doing this okay you get a gunsmith fit firing pin stop okay which again when I go to put this into the slide it won't go all right so we'll show you how to fit this in the next video how to fit a firing pin uh stop plate um and it's a little fat so we're going to end up putting on a surface grinder grinding it uh radioing the edges slightly and then fitting this tightly and again that will generally stop will stop for sure your clocking of the extractor the extractor clocking back and forth so that's really the most prestigious way if you want to call it the proper way you know most guys will want to do it with a with a like a fit style firing pin stop plate now other people you know you know they don't really care about it they don't want to spend the money they don't know how to really fit it they don't have the tools they don't want to take you to a gunsmith regardless what do you do then okay so there's a couple of ways and we'll show you some close-ups of this also one is obviously when I put this in here and I check extractor tension and what do I have right here around you'll see here uh extractor tension on this is actually extractor tension on this is actually a little tight even which is kind of strange so again I’ll end up re-tensioning the extractor after all this anyway um but there's two things that you can do to tighten this up and one is when you're re when you're re-tightening the uh when you're redoing the extractor tension either loosening or tightening it you know a lot of people they want to bend always toward the middle of the extractor which yes that's fine um and that is proper the other thing you can do is actually bend the back of the barrel here slightly and I’ll show you how to do that with just putting the barrel on the vise bending it this way slightly which will give you more tension uh you know actually act like a clamp and that and be more tension on the actual firing pin stop plate so it's not so loose okay so that's one way that we can actually correct what's going on here again I kind of prefer doing it this way with a with a with a gunsmith fit firing pin stop but again a lot of people do it this way also okay folks we're going to just show you here uh prick punching the stop plate and again you know we're using a stainless one here this is actually a gunsmith one but we're using this because it's easier for you to see on the video the black one doesn't really show much so again there's a couple ways to skin this cat you can go there and you can just put those punches toward the edges and deform that material just as I’m showing you here okay and you can do a few punches on this side also so again that's one way to do this all right the other way we're going to put it up in the vise jaws and you can do the back side so you'll notice on your slide stop here you've got you know nice edges here so again you can take it put it up here in your vise clamp on those edges that are there okay so it cradles it and then you can just do it on the back side okay so again you just put some punches you just deform the metal just a little bit and you bird it up and again that's going to make it tighter to go into the pocket in the uh in the slide and hopefully help you from the extractor clocking or from the firing pin stop plate falling out of the gun that's another thing and then what will that do well that'll generally start giving it so it gives it you know it'll burr up that material and give you a little bit more friction fit going in like I can I can't put that in all the way now without taking a little hammer I got one of these little hammers and I just jewelers hammers and tap it up in there so now you can see it's fitting tighter just from those little bit of prick punch marks and doesn't just fly right out now again the only thing you got to look at did that really stop your extractor from clocking back and forth the only way you can really check that is by you know putting your extractor back in and generally when an attar extractor just falls into the slide like that it's going to clock almost all the time unless you have a really tight uh firing pin stop plate so again I’ll put that up in there now I don't have the firing pin or firing pin spring in there so I’ll just hold it with my finger here my index finger on the bottom and I’ll try to move it and actually that did tighten it up some so it's not really clocking very much it's still got a little bit of clocking on the bottom area but not as bad as it was so again you know a few more uh you know swage that a little bit more and that will generally take care of that clocking issue now again when you when you when you fix your clocking issue what do you want to do well you definitely want to check your extractor tension again and then re-tension the extractor and we'll get into that here shortly in the next couple videos on uh you know doing the extractor tension which we've done that in the past on some on the top ends but uh we'll do it again and get some more close-ups of that so again the other way is like I said we can just bend the barrel we'll show you a close-up of this I’m going to probably get out of the frame here a little bit okay folks here we are at the vise and again this is just a standard vise you can buy at any hardware store there's nothing special I know I don't have soft jaws in here and you know some people are going to be like oh my you're going to scratch everything well what I do is I always put rags in the vise okay and again I’m not putting that much pressure on things like this extractor and that I usually use rags I usually use a micro cloth I don't have a micro cloth handy here but we're just going to use this rag for right now and I’m going to actually clamp this into the vise on the barrel just lightly okay and again you'll see how it is parallel with the jaws of the vise and then what am I going to do I’m just going to take it and I’m going to bend it so I’m actually putting the pressure so my fulcrum point if you want to call is going to be back here by the barrel okay let me get my favorite little scribe here and it's going to be back here by the barrel so I’m going to put more tension in this area right here so it's actually bending that barrel and it's going to create kind of a clamping uh effect of the barrel now we already had heavy extractor tension on the cartridge when we had this end when it was almost like falling into the gun so obviously this front section I’m going to have to bend the front of the hook out this way okay when I do this and again this is we're doing it this way why because we it's just another option for not fitting a gunsmithing fit firing pin stop plate so again it's just another option okay so here we go I’m going to take it and usually I just take my fingers and I just give it a little bend okay and once that bend is done and you'll see even the vice I don't have it excessively tightened I mean I’m tightening this bite just with one finger that's the only pressure I got on it very slight pressure all right so then what am I going to do I’m going to grab my slide I’m going to take this and I’m just going to see if this how this is going to fit in here and it's still a little looser than I like on the back so you take it in a little bit of stages here so I’m going to take it again clamp it in here again I’m one actually finger and I’m going to take it a little bit more pressure on it look at it you'll start seeing it it'll have a nice curved bend to it take it oh yeah now I can feel a little bit of tension so what we'll do now is we'll see how this works with over here with the clocking okay folks now we just finished uh bending the back barrel here slightly and we'll put it into the slide and then you'll feel the resistance there's more resistance kind of locks into place nicely now I’m not even going to put the firing pin or spring in yet I’m going to take the stop plate tap that into place and I’m going to check my clocking now ah beautiful no clocking at all very nice okay so you know again that worked out worked out perfect again it will it'll work better you won't have the extractor slopping back and forth in there um one other trick as you as you work on the extractor uh you know and bend the extractor slightly if you bend the back of the barrel sometimes it's a little bit harder to get out of the out of the slide and if you take a screwdriver and start reefing on it from back here you're usually going to get scratch lines on the back of your slide so again mar index card I take an index card just put it over the top like that take your screwdriver underneath and then start pulling it up you'll see it'll start coming out I’m hooked on the breech face here a little bit so I’m going to go in here I’m just going to push on that hook just a hair pushing it in and then it will start coming out more pop out more and there you go extractor back out so again we'll show up in the next video fitting uh the gunsmithing style stop plate and uh you know that like I said that's the most proper way of doing this but again this is the old-school way of a lot of people in the field would fix their 1911s by just you know taking a prick punch punching those side plates there um you know or bending the back of the extractor barrel now again once you've done that what do you got to do again you got to take a dummy round and ex and check your extractor tension always check your extractor tension again because that's going to definitely change as you change the dynamics of the extractor itself so you definitely want to go ahead and check your extractor tension and we'll get into that too again in the next few videos um you know attention to the extractor because that's part of your feeding and function also for that okay guys thank you very much uh we'll have more videos coming soon thank you for all the support fusionfirearms.com