- Category

-

- Bushings 51

- Compensators 19

- Links 15

- Home

- 1911 Parts

- Barrels

Barrels

A hand-built firearm gives you pride of ownership and bragging rights. But you can’t successfully build a 1911 pistol if you don’t understand essential components like the barrel and its roles. Remember, a gun can’t be a gun without a functional barrel.

We at Fusion Firearms know everything there’s to know about gun barrels and are willing to share our knowledge with you. That is why we are about to walk through the essentials, like the definition of a gun barrel, how it works, available types, and the components required for assembly.

What is a Gun Barrel?

The barrel of a gun is simply the long metal tube made from high strength alloy steel that the bullet moves through after you pull the trigger and igniting the cartridge. Most all modern rifle & pistol barrels have rifling, which have spiral grooves machined into a specific bore diameter based on the caliber/bullet diameter being used. Their role is to stabilize the bullet’s flight and boost accuracy by spinning it faster as it exits the firearm.

How a Gun Barrel Works?

The barrel is a critical and precision-made part of your firearm. It serves a crucial role in facilitating the conversion of chemical energy in rapidly expanding hot propellant gases to kinetic energy. The fired bullet needs energy to function as designed, this energy is created by the burning gun powder to move it down and out of the barrel.

Also, each barrel, due to its machining, produce unique markings on the projectile. Examiners often use the markings on fired projectiles to determine if a particular projectile was fired from a certain firearm.

Typically, a barrel is linked or assembled to the receiver on a shotgun/ rifle or frame/slide on a semi-automatic pistol or the frame/receiver of a revolver or break-action. The receiver, frame or frame/slide combination houses the firearm’s operational parts.

Basic 1911 Barrel Nomenclature

The basic description of the mechanic workings of a 1911 pistol barrel are listed in the diagram below.

Types of 1911 Pistol Barrels & Basic Gun Barrels

Bushing Barrels

Bushing style 1911 pistol barrels are the original Government design and are the most widely used. These barrels are designed to work with a bushing at the muzzle end. This bushing is designed to support the muzzle end of the barrel and makes for repeatable lock-up. It also has a secondary mechanical value as to wipe debris form the critical “lock-up” point, during operation.

Bull Barrels

Bull barrels are used in rifles and pistols. In rifles, they do not taper or narrow down towards the muzzle. The barrel is basically a straight tube with no additional machining for contour or weight relief. On the other hand, the bull barrels used in 1911 pistols are larger in diameter at the muzzle than the standard bushing style barrels. Also, generally most bull barrels will not use a bushing at the muzzle end..

A good example of a bull barrel is the 1911 bull barrel. 1911 bull barrels are often used in pistols being set-up for action shooting games and shorter barrel/defensive applications. The most common of the shorter barrel variants are sizes such as the Commander, Officers, and Defender size pistols. Bull barrels are also use by some for more “Weight-Forward” pistol set-ups. By adding weight to the firearm’s front, it will generally reduce muzzle flip.

Match Grade Barrels

As the name suggests, match-grade barrels are quality components best-suited for shooting sports, competitive matches and long-range hunting applications. What makes a match barrel and match barrel; start with higher grade stable material such as 416R Stainless. The “R” stands for “rifle grade” which means the material goes through rigorous testing, during and after manufacturing, for optimum mechanical properties and defects. Next, the barrels are “gun-drilled”, reamed, hand honed, machine broached and honed one more time. During these machining operations the critical bore diameters are checked with highly accurate calibrated “air-gauges’ to ensure maximum accuracy.

If you want a gun barrel with extremely high accuracy standards, get a match-grade barrel. It incorporates many design improvements over standard barrels and will increase your chances of higher accuracy hitting the target and acquiring tighter shot groupings.

Match barrels are machined to exacting tolerances. In addition, a small amount of material is left on certain features of the barrels. These are call “Fitting Points” and you can refer to Fusions educational barrel fitting videos for help.

Heavy Barrels

Simply put, heavy barrels weigh more and have thicker wall thickness than standard issue products. These, too, are a favorite for competitive shooters because they are better at absorbing vibrations, and the mass they add to the firearm plays a vital role in lowering the recoil. Most “heavy barrel” application are used in rifle bench-rest and long shooting.

Threaded Barrels

Barrels are threaded at the muzzle for a wide range of applications from suppressors, recoil compensators and muzzle breaks. For 1911 pistol applications there are various US Standards for pistol barrel threads for many accessories items. Basic US Standard for suppressor threads are as follows, 9mm .500-28, 10mm/40 cal = .562”-24 & 45 cal = .578-28. Also, many compensators adaptors will also use these same standard threads. Some compensators will use .575-40 for bushing style barrels and .685-40 for many bull barrel styles.

Fluted Barrels

Fluted barrels add a small amount of mechanical advantage, as the dirt and debris during heavy shooting will generally settle in these grooves allowing for the mating lock-up surfaces to remain somewhat cleaner. Most people like the fluted barrels for more aesthetic reasons on building a very rugged and distinctive look to their pistol. Basic styles of fluted barrels are straight and spiral fluting, both share the same basic mechanical values.

Barrels for purchase are also made from different materials. Popular options include

Stainless Steel Barrels

Stainless steel barrels have been in use since around the mid-1900s. But, Builders and shooters widely embraced them recently. The main reasons for this is that stainless steel barrels are better at resisting corrosion and erosion than standard chrome moly barrels.

Going with stainless steel products is a good idea if you want 1911 barrels that can resist corrosion and stave off heat erosion.

Chrome Moly Barrels

Chrome moly barrels for guns are made from a material known as the chromium-molybdenum alloy or 4150. This alloy is was designed for high wear resistance and durability. It is favored by many action shooters and is a good choice for rifle barrels that are used in “High-Fire” & “Rapid-Fire” applications and those associated rifle platforms.

With the above in mind, a chrome moly barrel can serve you well in a firearm likely to sustain rapid fire. It’s also a splendid choice for shooters seeking decent accuracy and good corrosion resistance.

Chrome Plated Barrels

Chrome plated gun barrels are generally manufactures from 4140 or 4150 alloy carbon steel and at one of the last manufacturing operations, a thin coating of hard chrome is applied. Hard chrome is a very strong, durable and corrosion resistant coating when applied properly. Chrome plating applications for barrels have been around for a very long time starting with military firearms with bores and chambers chrome plated to improve durability and corrosion resistance.

A chrome plated barrel can serve you well in a firearm platform for rugged used. This process will also add many years of consistent performance due to its high wear and corrosion resistance.

Carbon Fiber Barrels

Carbon Fiber Barrels are ideal for lightweight firearms. Generally, the barrel is not manufactured entirely of carbon fiber. The carbon fiber is a “wrap” or housing around a much thinner than normal steel liner barrel. Depending on the method of manufacture carbon fiber material can lead to improved harmonics and boosts shot-to-shot accuracy. Again, this is dependent on the manufacturing techniques and assembly method of the carbon fiber barrel. Moreover, since the material is lighter than a full diameter stainless steel barrel, it does lend itself to lightweight applications.

Barrel Ramp Cuts

The 3 main ramp cuts on 1911 barrels are:

Standard Ramp

The standard barrel comes without a ramp which means the feed ramp on the frame will be the main guide for rounds to chamber in your barrel. The barrel will have a chamfered relieved area at the mouth to aid in feeding. This is commonly known as the barrel mouth or sometimes “Throat”. A standard barrel does not require any additional machining to a standard Government style 1911 frame.

Clark/Para

The Clark/Para style barrel is what the industry calls a ramped barrel. This barrel has an integral feed ramp already machined on it and this takes the place of the standard frame feed ramp and adds additional cartridge support to the barrel. The standard feed ramp in your frame will have to be removed and further machined to fit a Clark/Para Barrel foot profile, if your pistol is not already set up with the Clark/Para barrel. The difference between the Clark/Para ramped barrel and the Wilson/Nowlin is you will notice on the Clark/Para barrel foot there is a radius cut that will slide into the modified feed ramp of your frame. For the Wilson/Nowlin ramped barrel the barrel foot is square.

Wilson/Nowlin

The Wilson/Nowlin style barrel is again what the industry calls a ramped barrel. This barrel has an integral feed ramp already machined on it and this takes the place of the standard frame feed ramp and adds additional cartridge support to the barrel. The standard feed ramp in your frame will have to be removed and further machined to fit a Wilson/Nowlin style barrel foot profile if your pistol is not already set up with the Wilson/Nowlin barrel. The difference between the Clark/Para ramped barrel and the Wilson/Nowlin is you will notice on the Clark/Para barrel foot there is a radius cut that will slide into the modified feed ramp of your frame. For the Wilson/ Nowlin ramped barrel the barrel foot is square.

The Clark/Para & Wilson/Nowlin ramps are machined differently and they do not interchange. Please consult our Fusion Firearms barrel videos for more clarification.

What is a Barrel Crown

A barrel crown is the additional machining at the muzzle end of the barrel. This machining is termed “Crowning” a barrel as it allows for an equal and smooth transition of the projectile as it leaves the barrel and aids in consistent accuracy. If a crown is damaged with dings, dents or improperly machined, accuracy will suffer.

Standard Barrel Crown

A standard barrel crown is generally a radial machine cut that starts from the outside diameter of the barrel to slightly larger than the inside diameter of the lands & grooves of the barrels rifling.

Flush-Cut & Target Crown

https://fusionfirearms.com/flush-cut-target-crown-barrel

A flush-cut & target crown is a term used for many target crowns on match 1911 barrels. A target crown can be flush-cut to front edge of the 1911 barrel bushing. This is where the term “flush-cut” is derived. The “target crown is generally an angular machined surface from the face of the barrel to slightly exceed the diameter of the lands & grooves of the barrels rifling. This angular cut is generally 1 straight cut or a compound angle consisting of 2 cuts. One primary angular cut to end just before the bores lands & grooves and a secondary angle to end just past the grooves creating a matting tangent line on the primary first angle. On custom and higher quality products this crowning is generally hand polished to perfection.

Components of the Barrel Assembly

Barrel assembly requires you to have the following components:

Basic components of a barrel assembly are:

A- Barrel

B- Barrel Bushing

C- Barrel Link

D- Link Pin

Bushings

If your pistol set-up uses a barrel bushing; during assembly, you should first slide the barrel into the slide until it reaches the breech-face lock-up point. Next, add a drop of gun oil to the slide bushing race cut and muzzle outside diameter of the barrel. Then place the bushing over the barrel muzzle and insert it into the slide. Ensure that you have the “Locking-lug” clocked properly so that the bushing will go into the slide. Then turn the bushing into its slide race and insure it is moving freely and seated at the face of the slide muzzle end. A proper fitting barrel bushing is critical for high accuracy and repeatability shot to shot. If your bushing is hard to turn use a 1911 bushing wrench to aid in assembly. These scratch resistant wrenches are available on our fusionfirearms.com website.

Barrel Link

The barrel link will be working a swivel link that attaches the barrel assembly to the frame via the slide stop and allows proper “Lock-up” in battery of the barrel in the 1911 assembly. A properly fitted link is essential for good accuracy and a dependable pistol. There are many link sizes available through the Fusion website and you should understand what is the best size for the lock-up of your pistol. The standard link, and generally most suitable for most applications, is the No.3 which is .278” center to center of the functional holes of the link. Additional link sizes are available for optimum fitting purposes and theses are generally manufactured in .002 to.004” increments. For example, a No.4 link will be +.004” Center to Center of the hole locations, meaning .282” and so on. You can also consult our educational barrel fitting videos for further explanation.

Link Pin

The link pin is securely assembled through the barrel foot and corresponding link hole. This assembly generally is completed with a pin punch and hammer. Once assembly is completed, ensure that the link will; A- swivel freely, B- that the slide stop pin will ride smoothly when inserted in the link hole and manually move the slide stop pin the entire travel of the barrel foots functional profile. This should move without any binding, then add a drop of gun oil to the link pin area and barrel foot profile. The barrel is now ready for assembly.

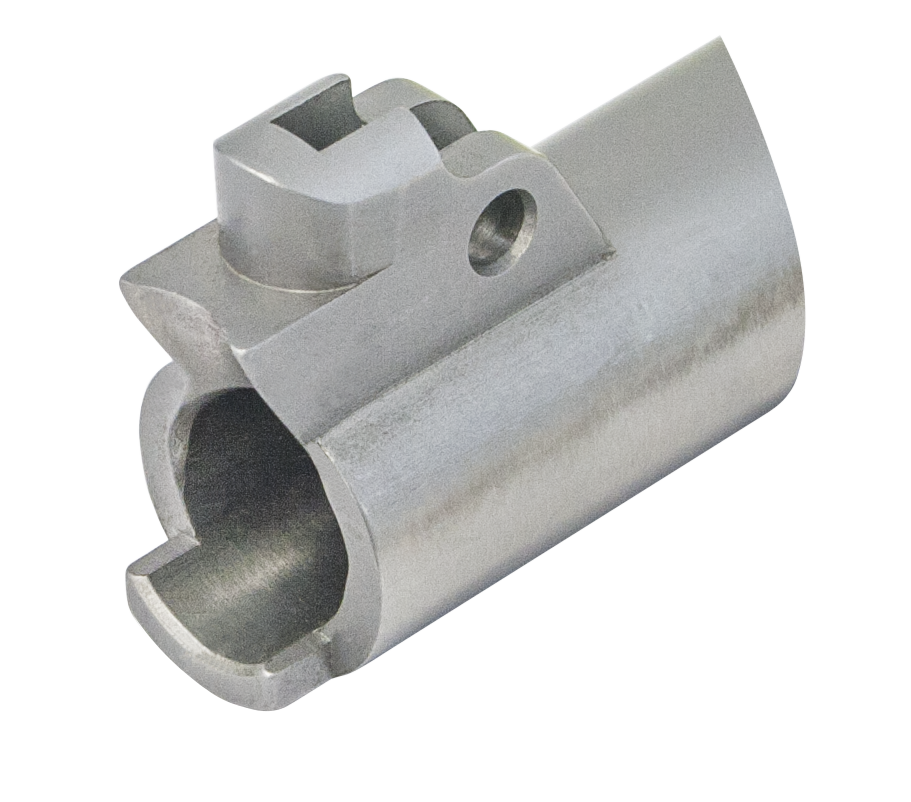

Barrel Accessories - Compensators

A compensator forces a firearm’s muzzle back to the original position after firing and counters recoil by redirecting some propellant gases and allowing them to escape upwards.

On that account, if you want your 1911 to always get back on target quickly after a shot, ensure it has a compensator.

Get Top Quality Components from Fusion Firearms

At Fusion Firearms, we know why your firearm needs top-quality components. That is why all our 1911 Build Kits come with exquisite barrels CNC machined from Bar-Stock. Most importantly, our products have no plastic.

Don’t take our word for it. Visit Fusion Firearms and check out our 1911 Build Kits today! If you need more information, contact our team without hesitation. We are here for you.

Show more

Show less

Position

Product Name

Price

View as

Grid

List

Items 1-12 of 23

12

15

30

- To TopShop ByShopping OptionsMy Wish List