1911 Barrel Fitting (Ep.3) | Where To Start! | Fusion Firearms

0%

In this video we will show you how to fit a 1911 Barrel and what common interferences you might run into when fitting a barrel. This is the bare bones when you first get started. This video will go over fitting your Barrel to your Slide, Frame, Slide Stop, and Barrel Bushing. As always have a great day from the Fusion Firearms Family!!!!

1911 Barrel Fitting Ep.3 Transcript

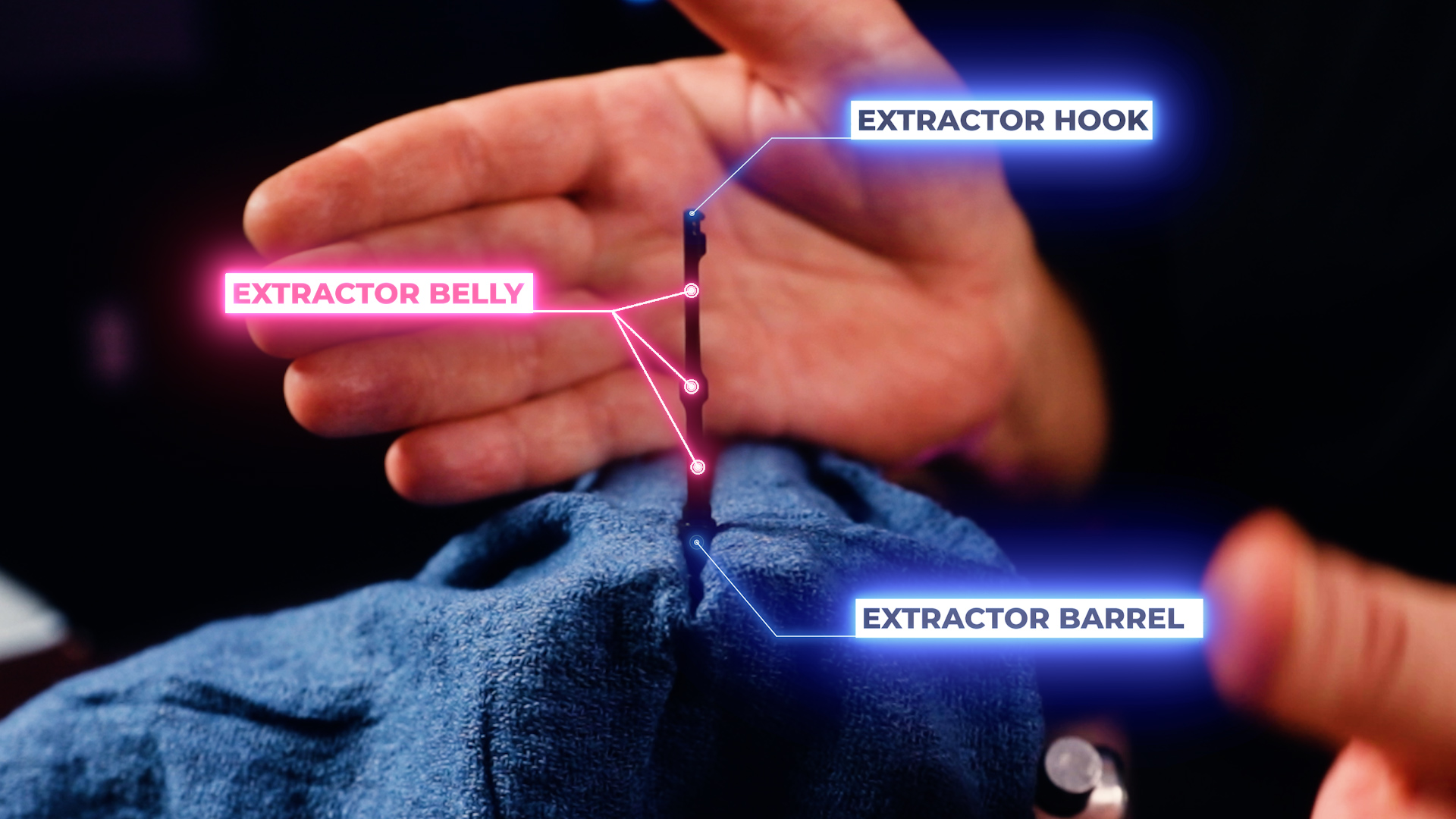

hi folks Bob Serva from fusion firearms! today we're going to get into a little bit of more of barrel fitting basics one of the reasons I’m doing this video and we're not going to get into anything real specific on fitting we're going to get into this video more of the procedure okay the steps you need to take the parts you need why am I doing this well we will also be doing actual barrel fitting and fitting all the parts into the into the assembly for you these have all been pre-fit this is a pro series custom job we're working on but I’m getting a lot of questions from people like bob can I send you my old barrel because my match barrel doesn't fit because it's too tight and can you make it like that can I send you just the slide in the barrel then can you just fit the barrel into the slide and the answer is generally no or maybe okay and why is that well there's a certain process okay or a recipe you want to have when you when you're building a 1911. and regardless to if it's going to be a tight match gun or you're just fitting something together for recreational shooting and that that the steps should be approximately the same okay so what do what do you need to actually make sure that you're going to put a barrel into your 1911 and it's going to fit properly again does that mean it's going to feed does that mean it's going to function no okay because tuning the barrel and tuning the gun for the barrel is a whole another step okay so I also have people that will say oh I set you in my top end and I set you in the lower I wanted the lower fitted to the top end okay we fit the lower to the top end oh it doesn't feed well you didn't ask us to tune the firearm okay which again is a whole separate separate part of gunsmithing it's a whole separate job compared to fitting the barrel and what needs to be done to fit the barrel so when I look at the actual basics around this what do you need well you need your frame you need a slide you need your barrel and a link Lincoln pin you need a slide stop and you need a barrel bushing those are your basics those are the basic parts you're going to need at least to start this recipe to get it going all right so what where do I start first well where I start first is from a stripped frame and a strip slide okay nothing in it no ejector no disconnector no anything why because you want to feel how things are fitting basically let's make sure that we have a strip slide and a stripped frame so we're not getting any interferences from the ejector the disconnector the extractor anything of that nature and then let's make sure that we have a freely fitting frame and slide and you don't feel any other resistance that you've got hang up somewhere on your rails or hang up on the injector and when you when you're I’ve had people that they'll go and they'll fit their frame and slide and then next thing they're like oh that feels really tight then you take the ejector off and it's sloppy because it's riding against the ejector so again you don't want any of these other variables thrown into what you're doing and while you're doing the the pre-fit if you want to call it for the barrel so number one this this barrel or this frame and slide are extremely tight it's a nice ground and then lap fit frame and slide so you can see it's actually maybe even a little too tight but it's nice okay so first I’m going to do that I’m going to make sure that the frame and slide fit together there isn't any strange resistance going on and again what I mean by strain restraint resistance the disconnector is not holding back the slide the ejector is not rubbing on the slide I don't have something weird going on in in when I’m fitting up these other parts okay so what am I going to do next well next I’m going to take my barrel and I’m going to check the foot of the barrel here okay which will show some close-ups of this which it's it's right in this area the barrel foot and generally the way we have our match barrel set is generally you have a couple of thousands to take off right here using a number three length on the barrel feet and then sometimes a little bit on the back side here why did we set them up that way we set them up that way so it'd be a good tight fit it's easy to fit and again it allows you at home with simple basic hand tools some round files things of that nature a felt bob to polish it in after you file a little bit you can actually fit this and do a pretty good job of it right at home the barrels we produce now and the way we tolerance those also the hood this hood area back here is about four thousandths long from mil-spec some people just leave it the way it is as it locks in sometimes you might have to take a little bit off here and you might have to take a little bit off these side two side walls and again it will really depend on how your breach face is caught and that 157 ledge on the other side again it's 157 for the for the 45 and I believe in the 9 millimeter it's like 140 right around so depending on the tolerances in your in your pistol that's why we leave a little bit of meat here some guys like the bp here on the side some guys like to bp on the hood some guys want to bp down here everybody likes a little bit of rub on the on the barrel feed itself so we leave a little bit of meat there and we have an awful lot of people using these barrels now even other manufacturers are using these barrels for their better match grade guns and guns that they want a kind of a match fit barrel because there's much less fitting you don't need a lot of special equipment you're not taking hours and hours to hard fit a barrel and the accuracy has been just wonderful with these barrels so our recipe with the barrel is really working out well so what do you want to do next okay well next you're going to take your slide stop okay so here we have the link and the pin assembled and we've already conditioned the actual barrel feet themselves right here and then I’m going to insert the pin from the slide stop because the diameter of the pin is going to really weigh in your calculations on your link up and just with a little bit of pressure on the link I’m going to move this back and forth you can see it's a little tight because it is binding slightly but it's good enough to start with my assembly here and you'll see that in the assembly it's about right but and I probably will take a few more swipes with a file off this as I move up but you want to just take it I’m doing this backwards you can get in the camera it's a little difficult but you just take it and you'll see how I’m just moving it back and forth a little bit and make sure I’m not binding too much on the link here's actually what it should be like when I put like finger pressure down so that the pin is on the barrel feet itself and you can just move it slightly back and forth and that you can actually feel it it's a nice feel where you can feel you're getting decent contact but it's not binding now if I took this and actually put excessive pressure on it and even now it's not binding so that means that radius is really nice but you'll know it'll get to a point where you can't even move this down so then you'll have to you have to take a little bit more off the barrel feet area right down in this area right down in here again you can ink that up with a magic marker and you can see where you're hitting harder all right so what am I going to do next well next I usually just I put it into the frame I hold it into the frame I check for my slide stop position and I’ll put my slide stop in and I’ll just work it onto the barrel bed and see how it's fitting on the barrel bed and just make sure that I don't have any type of resistance here okay so what could I have going on wrong here well okay again I could have where it's not going to sit down on the barrel bed halfway decent because the barrel bed might need a little bit more trimming you do see some frames that will need that sometimes the radius just expanded slightly what else could it be well maybe the back side here of the barrel feet needs to be trimmed a little bit usually if you can't link down that's one of the suspects right there on the back of the feet here it when it's in the slide you can't get it to link down good that that could be an issue there so something to look at okay so in the frame you have your barrel bed here you've got a little bit of relief angle cut right here we call this basically the bulkhead area back in here this is a bulkhead also for primary bulkhead for the recoil rod and then we close like a secondary bulkhead but basically again this is one area that the barrel could bind up on underneath so you might have to take a little radius off the bottom of the barrel or add a little bit more chamfer right there also this barrel bed this one's fine but sometimes you'll notice you have very little bit of clearance on the sides of the barrel bed here so you might have to dress that slightly and take a little bit of material off both sides on the barrel bed so your barrel will seat right in the frame so that's just a few little interference points that you may have in there and just make sure it clears good make sure your pin your your link pin isn't sticking out where it's rubbing on the side walls inside the frame here inside the bulkhead area you're not rubbing on anything sometimes you'll be sticking out on one side and you'll feel some more resistance again you don't want any if you want to call alternative resistance going on in your assembly when you're fitting because a lot of it is feel you're going to feel it how is it linking down how is it linking out things of that nature and if you have something like again you're rubbing on the ejector disconnector is real stiff so the slide's coming back and you think boy it's kind of linking down hard but it's really hanging up on the disconnector it's like so there's things like that you just want to get it out of the equation so it's not becoming a variable in your fitting so next what we're going to do here again we're looking at a barrel fitting into the slide no bushing again also one thing I didn't mention that if you have a hard time getting the barrel into the slide a lot of times it's just these two little pads right here you need a little bit of file or buff work on that those two areas just for clearance to get into the slide so okay what am I going to do next well next I’ve already fitted this this barrel hood and again we'll be doing that out in the shop here eventually we'll show you exactly how we how we fit those so this one I’m going to I’m going to is fitted I like the way that fits I got a little bit of clearance on the back of the hood here and remember you're going to be sitting at approximately one degree angle or so as that swings up and links in even if you have a slight bit of clearance a though or two you're usually still going to get a bp or a rub there so after I after I do that my and I see yep that's actually going up into my lugs nicely a lot of times guys will send their barrels in they can't fit them first thing I look at is they've just thrown the barrel in here put a bushing in went ahead and assembled the frame and the slide and they can't get it to they can't get the barrel to link down or link up properly it's just kind of jammed and stuck there why it's not even going up into the lugs so step one after you've got your other parts somewhat fitted together is is the barrel seating up into the lugs and it's pretty easy to see that can you and I don't put a bushing in here again no bushing no barrel brush and no extractor either okay you don't want an extractor in there why again I’ve seen people they'll fit a gun they'll get to this point they think this is good they get everything going they lock it up and then all of a sudden they're having issues well it's because sometimes the extractor's a little long and the hook of the extractor is bumping up against the back of the barrel and then causing issues of un unlinking coming down out of battery so again look for those little items and again keep them out of the system right now so you're just focusing on the key components that you really need to fit the barrel into the into the frame and slide so after I get to that point I know my link is halfway decent right now it might be a smidge tight but we're still okay with that we can still link down I put it up into the locking lugs and yep it's fitting nicely up there next thing I’m do without a bushing again without a bushing I’m going to put it on the frame and slide this one like I said is really tight and then I’m going to take my slide stop put my slide stuff in now when I’m doing a setup I don't always engage the slide stop up into the notch here I usually just let it dangle just like this okay that's more than sufficient really you're working off the pin diameter right now so again that's another thing to watch out for somebody will set a pistol up with a 198 pin diameter in in the in the assembly that you're that you're doing next thing you buy a new slide stop and you notice your barrel is really linking down hard it's really coming off hard when you're starting to open the slide and you say well what's going on nine times out of ten it's because it's hitting the pin diameter is bigger it's maybe at a 200 now or a 201 and it's hitting that it's hitting the barrel feet real hard and it's having a hard time getting out of battery and linking down from that so again I’m doing this with no bushing and you see I have nice lock up decent movement when I again I’m going to hold my thumb on the back of the slide and I’m going to do the same thing here I’m going to see how this moves and oh yeah I can feel it you can actually feel when you're when you're hitting the bottom of the barrel feet by just putting some light pressure with your thumb on the back and just moving this back and forth and again you see I’m not banging with a hammer I’m not using excessive force I can just feel that it feels really nice it's just starting to get a little bit of resistance on the bottom of the barrel feet and that's beautiful the way that is okay so next I’m going to take the pin back out I’m just going to push everything forward we're going to take mar barrel bushing and put that in I’m going to take it right off the frame barrel bushing's tight use a wrench okay I’m going to put the barrel bushing in the actual assembly position straight down and then I’m going to take my barrel assembly again and I’m going to move it out and I’m going to move it back and I’m going to move it up into the lugs again yep it feels beautiful why I don't feel any binding I don't feel any springing okay if you feel springing usually you got to take a little bit either off the OD of the barrel or the internal diameter the id of the barrel bushing okay so those are something you want to look at because a lot of times if you if you when you have no bushing in here in the in the slide at all and you can feel that you have nice lock up okay you can feel you have nice free lock up no interference no hard interference okay great that feels beautiful now if I put the barrel bushing in and I go I swing it to the to the low position and I and I go and I’m like wow I can't even get up in my locking lugs now what's going on it's because your id of your of your barrel bushing and your OD outside diameter of the barrel itself are too tight so when that thing's trying to when the assembly is trying to swing up into the one degree approximate one degree position okay it's having a real rough time it's actually binding and springing you're springing the barrel you're actually springing the assembly and when you might be able to lock it up in the frame but again you're I’m going to tell you right now you're going to have a lot of inconsistencies as you break in the in the gun you're going to see the barrel is not going to be settling in well and your accuracy is going to suffer because it's always binding and as it's wearing in it's just not going to be a good fit so one thing you want to do again is make sure with the bushing in that that lock up feels just as good as it did before and it does okay so what's next so next frame again no ejector no disconnector no other parts get it out of there okay I’m going to put the frame on the slide I’m going to put our slide stop in and then I’m just going to rack it back and forth and yes it's locking up beautifully and again with just light pressure a few things I look for one I put a little light pressure at my the on the back of the slide I check the barrel bushing is the barrel bushing moving shucking back and forth all over the place that's one thing to look for maybe you need a little heavier outside diameter on your barrel bushing to keep that more consistent so that that's beautiful let's fit nice on top of that I’m going to take and I’m going to swing my slide stop and I can feel a little bit of resistance in there beautiful feels really good next thing I’m going to do I’m going to push down on the hood a little bit and there's no spring it's like solid as a rock so again that is a nice fit and that and that's and again you don't have any binding okay and a lot of times on barrel fitting there's people that go kind of extreme where it's like well I got to be hitting on the lugs and I got to be hitting on the back of the barrel feet and I also want to hit on the top of the hood and I want to hit on both sides of it you're basically and again some people will build them that way and that's fine if that's what you want to do but it takes tons and tons and tons of time you're out what your outcome generally is not really that much better than a regular fit barrel such as this and it obviously is better than a standard gray barrel but again with a match grade fit like this you're not going to see much difference in accuracy now if you're one of the top 10 ball shooters in the world yeah I’d spend my time on it but for the average guy that wants to go out and have fun shoot targets have a really nice accurate pistol it's it you don't need it you don't need it you don't need the expense of it and also the high maintenance of it so generally I like to see what do I like to see I like to see a little bit of rubbing on the pin on the on the slide shop pin just a little bit and I also like to see at least one contact point in most time it's either the top of the hood and or the backside on the 157 on a 45 you might see a little bit of rub mark there which is great once if you have too many places that you're making contact okay again those are basically contact points which as the pistol wears in it might take you a ton of rounds just to wear it in to where the barrel settles down and why do I say that because of the heat treat of the different materials you're going to get you're going to get things settling in different at different spots on the slide on different spots on the barrel feet on different spots on the bushing so again if you fit it way too tight it can be just as bad as fitting it way too loose okay so again there's kind of a happy medium there and again it's not a difficult thing but I want to make sure that people understand the steps that need to be done because so many people have the misconception that well I can just send you my barrel and my old barrel and I know it's going to lock up in in the frame and maybe it will maybe it won't I don't know I don't know what link it is we don't know the position of your hole in your frame the barrel bet in your frame another thing for check for interference while we're on the subject is right in here too this little angle you got the you got the bulkhead back in here in the frame and this little angle that is actually here on the barrel bed a lot of times that's for clearance for the barrel some barrels you'll see different manufacturers will have different barrel designs and back in this area here you'll see a radius sometimes you have to file that radius out sometimes the there's a smaller radius a bigger as those are just things to look for so as you're linking down if you feel interference sometimes you look at that angle right there because that angle will show where you're hitting you'll see some peening there and you'll see as the barrel is linking down it's actually painting right on that ledge so that's another thing just to look for and again if you have resistance and you're having issues a magic marker take a magic marker mark up the back here mark up the radius markup places on the barrel or markup places on the frame put yourself in lock up work it back and forth even if the thing is sticking on you can take it and just tap it with a with a mallet tap the slide when you're in battery take it bring it in the battery it's you can't get it in real good okay just tap it slightly tap it slightly tap it slightly tap it slightly when you pull it out okay and again you do that with your barrel on there when you pull the barrel out you'll see red marks on the barrel or you'll see parts where the magic marker is worn off those are your suspicious areas so again those would be highly suspect to go looking at okay I’ve got an interference there maybe that interference is here maybe it's on the side over here I got to take a little bit more material but again it's just those little things to look for and you'll find out sometimes that just by taking a couple of thousands in one place or the other boom she drops in beautiful so all right guys well that's kind of a quick overview of again kind of the ABCs of getting your barrel fit started and what you should be looking for if you got any questions put them below in the comments or give us a holler you put an email through our Tec help at fusionfirearms.com and we really appreciate you watching and the channel's growing great and we really thank you all for sticking with us thank you very much> CHECK OUT OUR MINDS CHANNEL:

https://www.minds.com/fusion_firearms

CHECK US OUT ON FACEBOOK!

-Facebook Tech: https://www.facebook.com/Bobs1911bench

-Facebook Info: https://www.facebook.com/FusionFirearms

CHECK OUT OUR INSTAGRAM:

https://www.instagram.com/fusionfirea...

Music: https://artlist.io/