How Firearm Finishes Effect 1911 Feeding | 1911 Feeding (Ep.6)

0%

Are you experiencing feeding issues with your refinished pistol? It's possible that the finish you applied is causing the problem. In this video, we'll delve into how different finishes can impact the feeding of your 1911 pistol.

Firearms Finishes:

How They Affect Feeding Performance In the 1911 Pistol

If you're a gun enthusiast, you know that the right finish can not only enhance the appearance of your 1911 pistol, but also improve its durability. However, it's important to understand that certain finishes can also impact the feeding of your weapon.

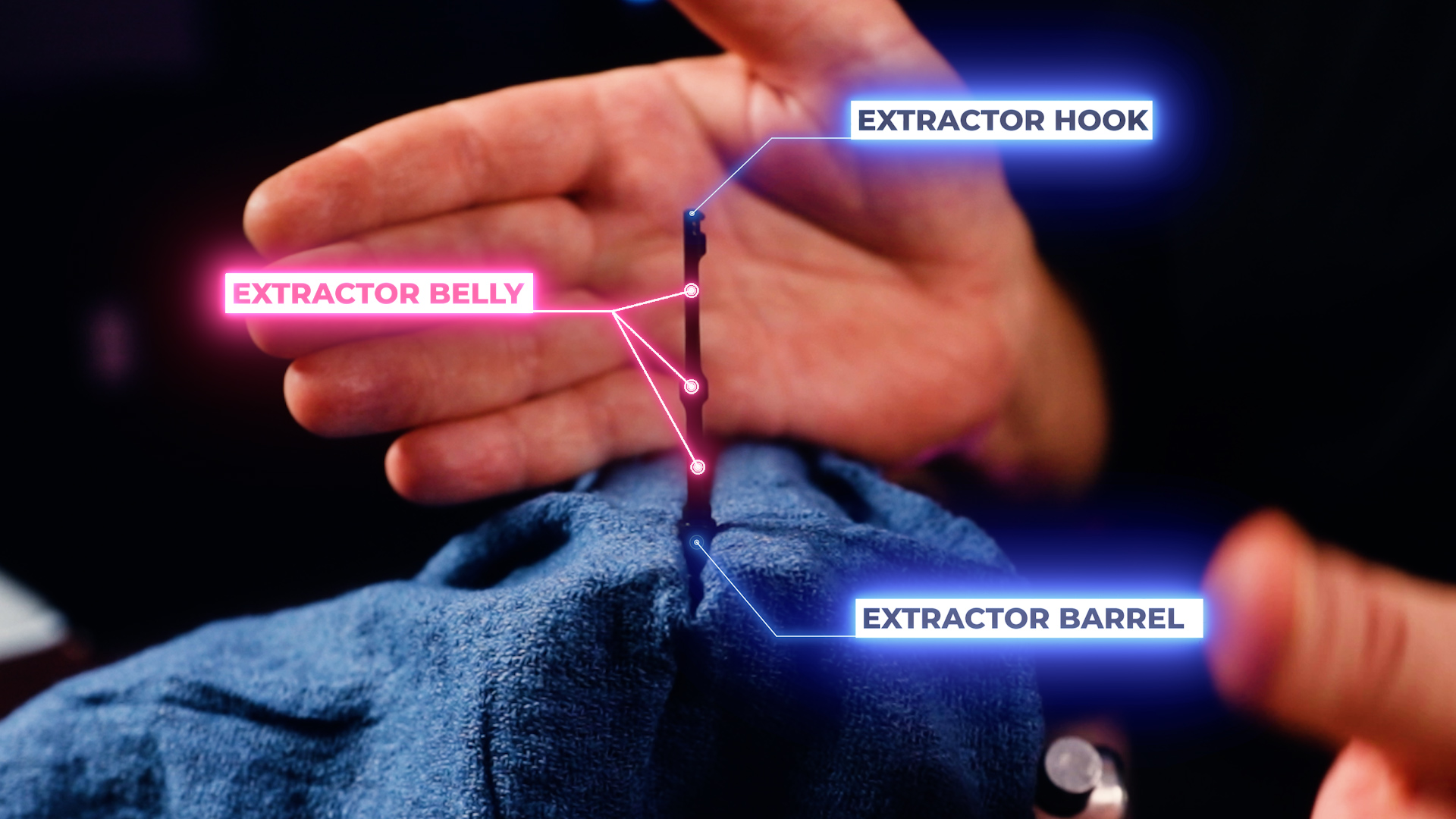

Imagine this scenario: you've just applied a beautiful cerakote finish to your 1911 pistol, and you can't wait to take it to the range. However, when you start shooting, you notice that the rounds aren't feeding properly. Frustrated and confused, you bring your gun to a gunsmith to see what's wrong. Upon inspection, the gunsmith discovers that the extractor hook is coated with excess cerakote, causing the rounds to get stuck.

This scenario may seem far-fetched, but it's actually not uncommon. Many gun owners don't realize the impact that finishes can have on the feeding of their firearm. That's why it's so important to understand the mechanics of your weapon and the potential effects of finishes on those mechanics.

Maintaining the proper functioning of your firearm is crucial for ensuring optimal performance at the range. One aspect that can significantly impact the performance of your weapon is the finish. There are various types of finishes available for firearms, including traditional bluing and modern options such as cerakote and nitrocarburizing. While these finishes can enhance the appearance and durability of your firearm, they can also affect the feeding of your weapon.

To ensure that your 1911 pistol is feeding properly, it's important to consider the following factors when applying a finish:

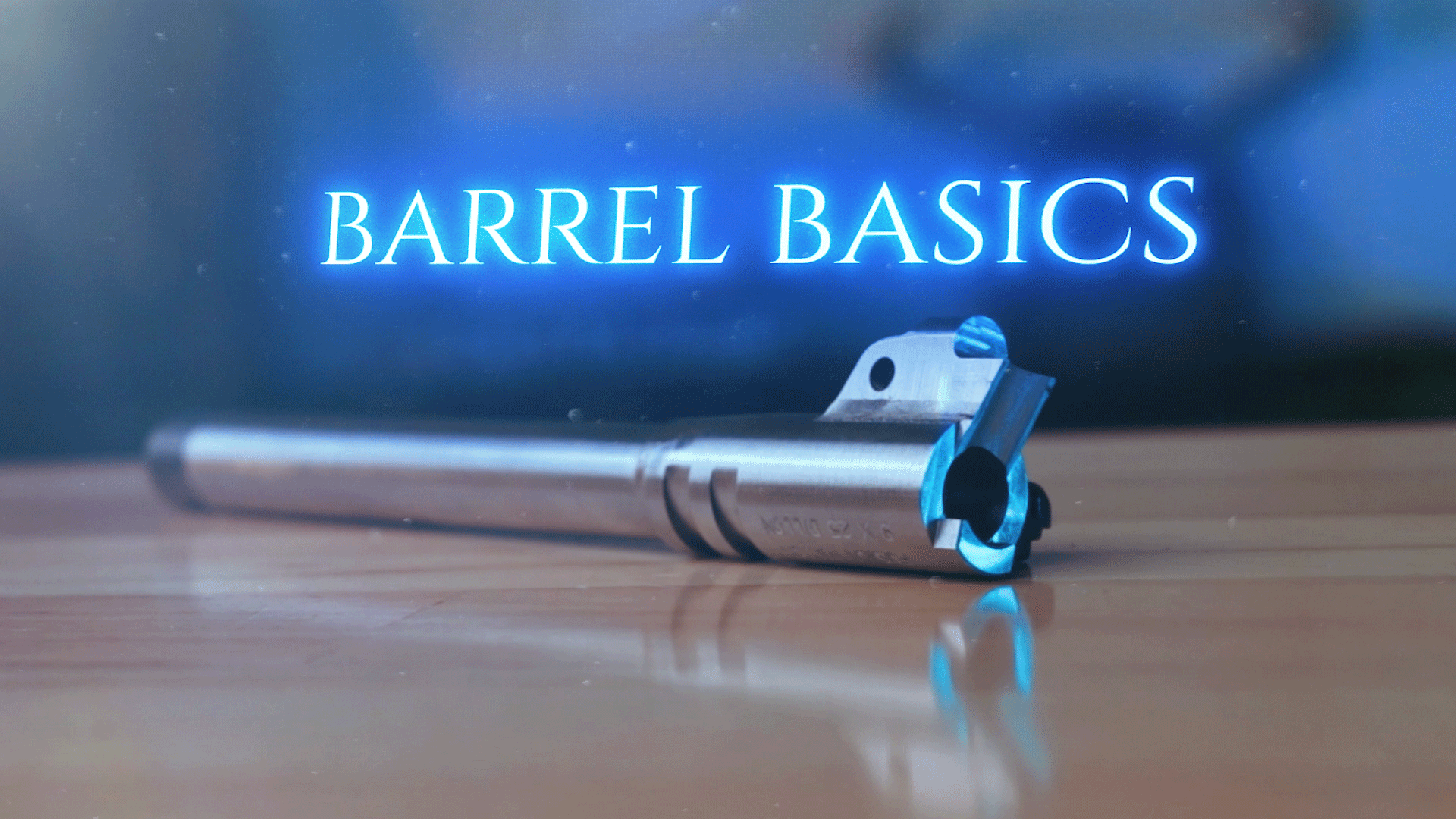

- Re-tune or clean up mechanical parts: Any mechanical parts that were adjusted prior to the application of the finish should be re-tuned or cleaned up afterwards. This includes components such as the extractor, feed ramp, and barrel throat. These parts may have been fine-tuned for optimal performance prior to the application of the finish, and if they are not re-tuned or cleaned up after the finish is applied, they may not function properly.

- Polish certain areas: To break in the finish and create a smooth surface for the rounds to feed on, it's a good idea to polish certain areas of the firearm. This may include the feed ramp, barrel throat, and breach face. By polishing these areas, you can create a smooth surface that allows bullets to feed more easily.

- Remove excess finish from the extractor hook: The extractor hook is a vital component that is responsible for extracting spent cartridges from the chamber and feeding new rounds into the chamber. If it is coated with excess finish, it can cause the firearm to malfunction. Therefore, it's essential to remove any excess finish from the extractor hook to ensure proper feeding.

By following these steps, you can maintain the proper functioning of your firearm and avoid any issues with feeding. Don't let a faulty finish ruin your shooting experience - make sure to properly maintain your weapon and keep it in top working condition.

CHECK OUT OUR MINDS CHANNEL: https://www.minds.com/fusion_firearms/

CHECK US OUT ON FACEBOOK! -

Facebook Tech: https://www.facebook.com/Bobs1911bench

-Facebook Info: https://www.facebook.com/FusionFirearms

CHECK OUT OUR INSTAGRAM: https://www.instagram.com/fusionfirea...

Music: https://artlist.io/

FULL TRANSCRIPT